Tile Adhesive

Tile Adhesive

Specification

| Parameter | Dudhi Tile Adhesive |

|---|---|

| Open Time | 10-15 minutes |

| Pot Life | 60 to 120 minutes |

| Adjustability | 20-25 minutes |

| Appearance | Grey Powder |

| Tensile Adhesion | >0.75N/mm² |

| Shear Adhesion | >8.00 KN |

| Coverage | 2-3 sq.ft/kg for 3 mm thickness |

| Water Demand | 25-30% |

| Ingredients | Cement+ Graded Sand+ Additives+ Polymers and Fillers |

| Density | 1400-1600 kg/m³ |

| Maximum Grain Size | 1mm |

| Shelf Life | 6 Months in dry unopened bags |

| Packing | 20 & 40 Kg. |

| Standard | Compiles the specification of IS 15477:2004. |

Performance

| Description | Conventional Method | Adhesive Method |

|---|---|---|

| Setting Time | 24 Hrs | 4-6 Hrs |

| Average Thikness | 20-25 mm | 3-6 mm |

| Curing | Minimum 3 days | No requirement |

| Workability | Insufficient | Excellent |

| Strength | Lesser | Higher |

| Skill Requirement | Higher | Lower |

| Wall Finish | Should be rough finish | Normal Sponge Finish |

| Water Proof | No | Yes |

Consumption of Material

- Consumption Per mm/ Per Sq. Ft.- 0.100 kg

- Coverage 13mm Thickness 30sq-ft/40 kg bag, 19 sq-ft/25 kg bag

Features & Benefits

- Eliminates two-step process of Sand Cement Plaster and POP punning

- Doesn’t require water curing

- No shrinkage cracks

- Non-combustible (when tested in accordance with BS: 476: part 4:1970), therefore a good form of

thermal protection to the building structure. - Use of light weight aggregates in the plaster mix help to improve Low thermal conductivity (0.25

W/m-K) as compared to Sand Cement Plaster (0.72 W/m-K) ** keeps room cooler in summer and

warmer in winter; saving in energy cost - The water absorption as per DIN EN 520 is less < 10%

- Excellent Capillary

- Water absorption coefficient test method —- BS EN 1015-18.

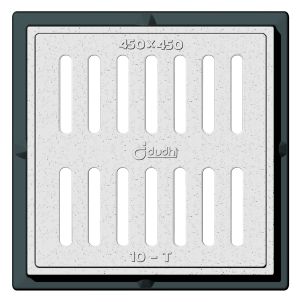

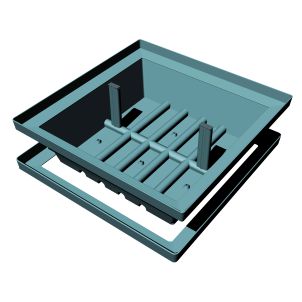

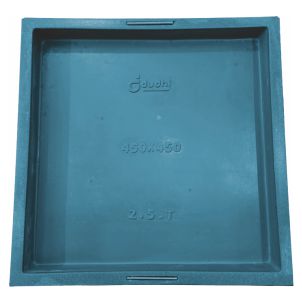

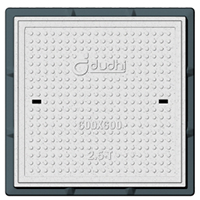

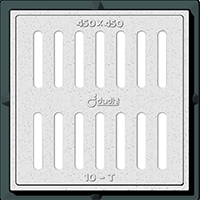

Available Sizes

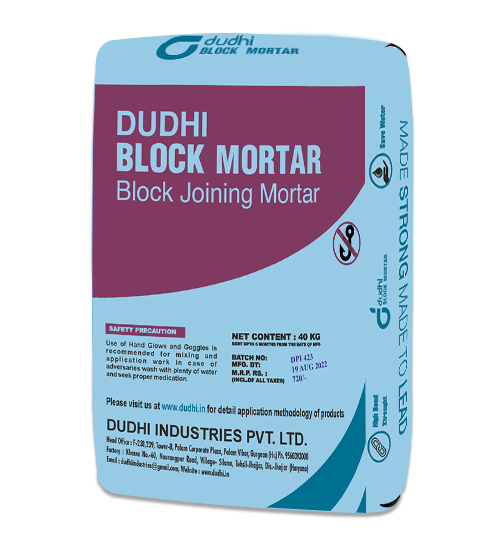

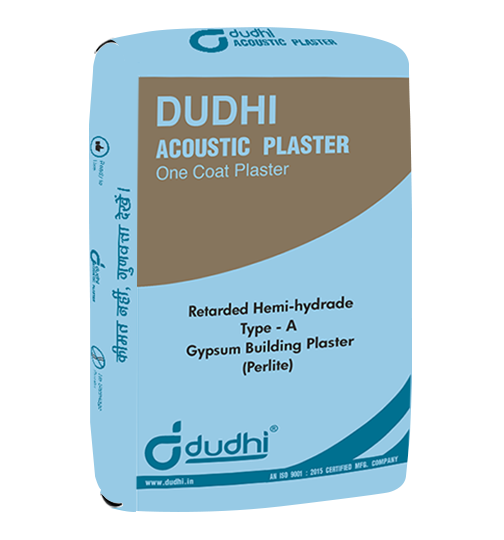

Identification & Packing

Dudhi Gypsum (Brick Solution) (Moisture Resistant) is packed in PP bags. The outer layer of the bag is printed with the product image, batch number, date of manufacturing, correspondence address and application instructions.

Backed by Superior Service

- Technical service team offers regular site training to use tools and technology to improve

productivity. - Intermediate site inspections and feedback.

- Recommend trained application Team.

- Largely distributed manufacturing capacity.

Testing Standards

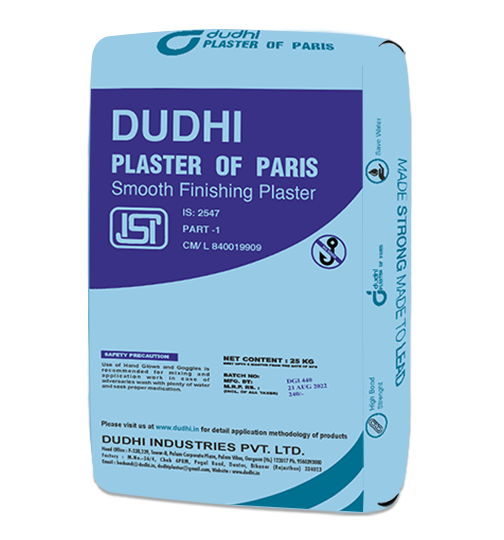

- Confirms to IS 2547 (Part |) — 1976 for physical & chemical characteristics

- Confirms to IS 2547 (Part Il) — 1976 for physical characteristics

- HSN Code : 252020, GST : 5%

Certification:

- Conforms and Certified to IS 2547: Part 1 and 2 of “The Bureau of Indian Standard” as per

licence number CML-8400019909 - Meets standards of Green Pro certification and qualifies as green product.

Storage & Handling

Dudhi Gypsum (Brick Solution) (Moisture Resistant) is supplied in 4OKg bags. The dimensions of the bag ensure that a well-filled appearance is presented when filled and the bags can be stacked on a pallet in a stable and well-stacked array. Bags should be stored dry, as absorption of water shortens the setting time, causes set lumps to (*) form in the bags and may reduce the strength of the set plasterwork. No hooks or any sharp tools should be used to carry bags from one location to another.

Application Procedure

Surface Preparation

- Clean loose particles, dirt, grease and traces of foreign material from the surface, if necessary by using wire brush/sand paper or by chipping.

- For Loose plaster areas, removes the defective material and replaster the area with Dudhi Ready-Mix

Plaster. - For Floors/walls, which are not even, replaster it with Pre-Mix Plaster.

Mixing

- Take clean water as per the water demand in a clean bucket add Dudhi Tile Adhesive.

- Stir continuously by hand to obtain a homogenous lump-free paste. Tile Adhesive paste should be like creamy butter.

- Allow the resultant paste to stand for about 5 minutes for the additives to dissolve.

- Re-Mix again for about 2 minutes and after that the ready mixture paste is now ready for application.

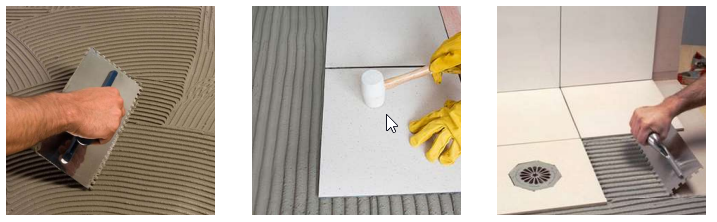

Application Methodology

- Dampen the surface to be tiled with clean water, allow the excess water to drain off.

- Using a steel trowel/ blade, apply the above mix to a thickness of 3 mm either on the wall or on the back of the tile. (but do not apply the paste on both)

- Using notched trowel remove the excess material, Put the tile in place and tap it gently with a help wooden hammer.

- Remove excess material from the side of the tiles by using a damp cloth or a sponge.

Precautions

- Store the bag tightly closed in a cool, dry place

- Keep out of reach of children and away from eatables.

- May be harmtul if swallowed. In case of ingestion seek immediate medical attention.

- Wear eye protection during application. In case of contact with eyes, rinse immediately with plenty of

water and if required seek medical advice. - It is recommended to wear suitable nose pad during surface preparation, mixing, application to

avoid dust inhalation.

Features