Overview

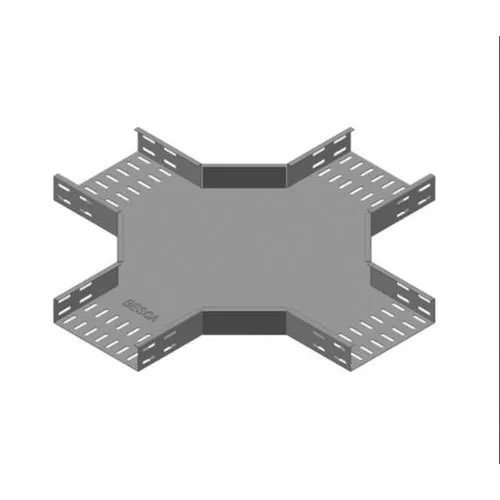

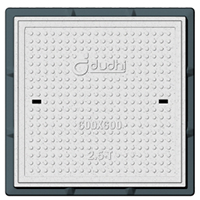

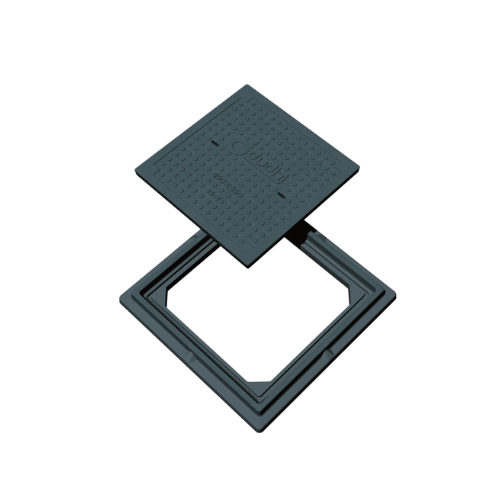

Fibre Reinforced Plastic (FRP) manhole covers have become an alternative to traditional manhole covers made of materials such as cast iron, concrete or steel. FRP is a composite material that consists of a thermoset resin matrix reinforced with fibres such as carbon or glass. These covers offer several advantages over traditional materials, including lighter weight, higher strength-to-weight ratio, non-corrosive, non-conductive, and longer lifespan.

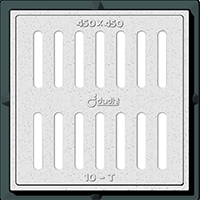

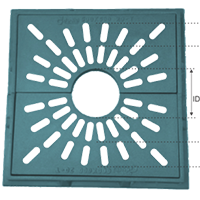

FRP manhole covers are designed with a load-bearing capacity that can withstand different types of vehicular and pedestrian traffic. They are also designed to prevent unauthorized access to the utility lines, underground storage tanks and other sensitive areas. FRP manhole covers come in different shapes and sizes, making them suitable for use in different applications such as sewer systems, drainage systems, and gas transmission lines.

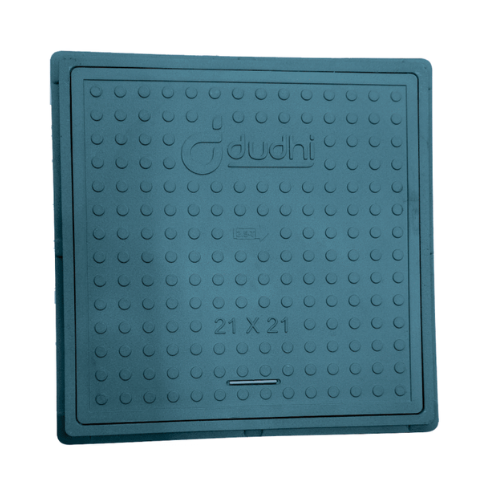

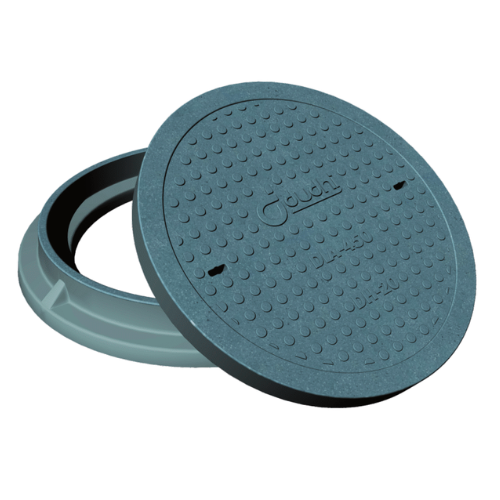

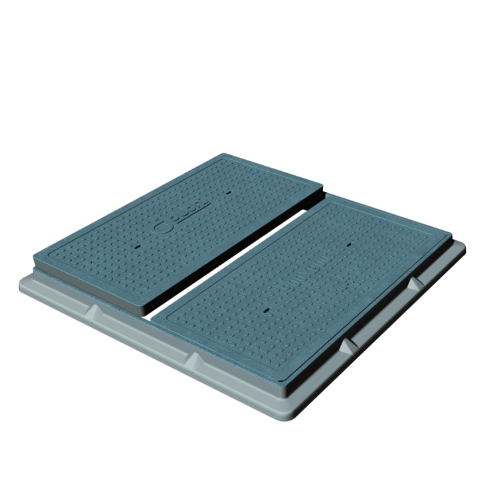

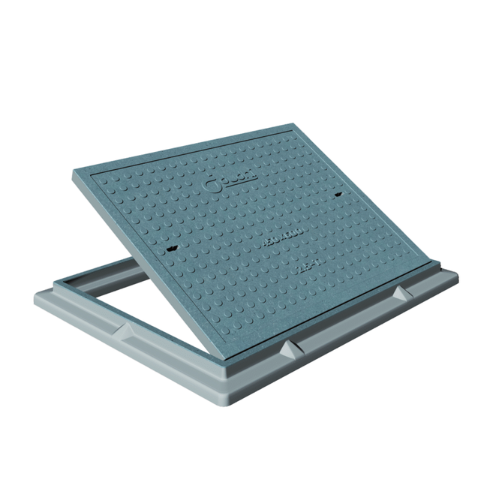

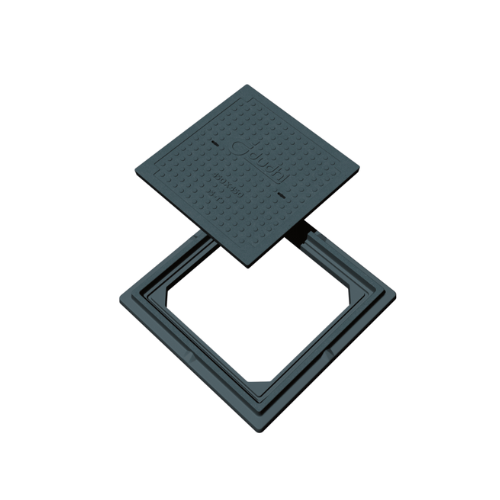

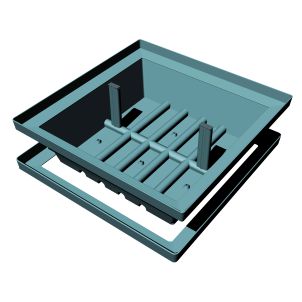

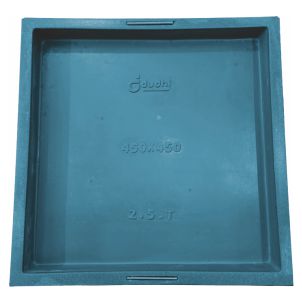

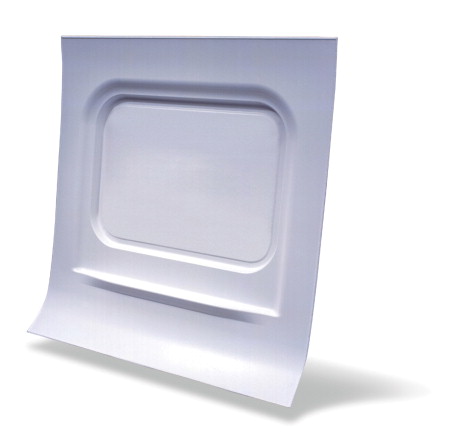

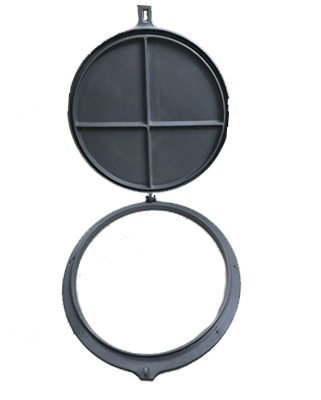

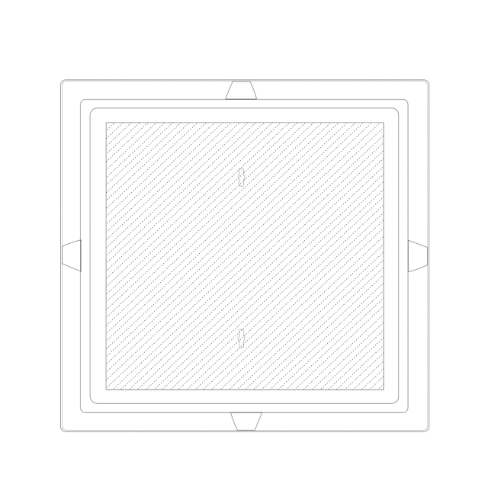

FRP Tank Cover

- Water tank cover made of Dudhi FRP product, represents a hygiene article.

- Functionally, it has to keep the water clean inside the tank.

- A special type of seal is used in between frames and top cover to make the cover air proof though outside water is not allowed inside the tank.

| Parameter | Dudhi FRP Products |

|---|---|

| Application | Green Belt, Sidewalk, Pedestrian, Driveway, Highway. |

| Surface Treatment | Anti-Slip, anti-UV |

| Technique | Mould pressing |

| Shape | Circle, Square, Rectangular or Customize |

| Color | Standard grey and as required on demand |

| Working Temperature | -40°C to 120°C |

| Service Life | More than 50 years |

| Working Condition | Anti Corrosion, anti uv, anti acid and alkali, anti-rusts etc. |

| Conduction | Non-electricity conduction and non-heat conduction |

| Noise | Less noise and lower vibration |

| Packing | Carton and as per customer’s request |

| Description | Cl | RCC | Dudhi FRP |

|---|---|---|---|

| Life Span | Moderate | Low | High |

| Strength | Moderate | Very Low | Very High |

| Cost | Moderate | Low | Comparable to Cl |

| Weight | Light | Heavy | Light |

| Manufacturing System | Manually Casted | Manually Compress | Molecular Binding Technique |

| Material | Cast Iron | Steel Fiber Reinforced Concrete | Glass Fiber Re-inforced Polymer |

| Water Absorptive/24hours | High Water Absorptive | High Water Absorptive | 10-30 grm |

| Carbon Content | 5-10 % | – | Carbon Free |

| Scrap Value | High | Low | Nil(Zero Value) |

| Anti Acid/Alkaline | Affected | Affected | Not Affected |

| Colour Range | Black | Concrete Grey | Range Available |

| Logo Embossing | Not Available | Not Available | Possible |

| Flexibility | Bend with load | Bend with load | Come back in bending |

| Custom Design/Size | Not Available | Not Available | Possible |

| Handling | Difficult | Very Difficult | Easy Compressive |

| Strength | Not mentioned | Not mentioned | 300-600 Mpa |

| Thermal Expansion | High | Negligible | Nil |

| Noise(vehicle movement) | Noise Generate | Noise Generate | No Noise Generate |

| Break Elongation Ratio | More than 10% | More than 30% | 1.3-10% |

| Corrosion Resistance | Affected with short span | Affected with short span | No Corrosion Affected |

| Abrasion Resistance | None | None | yes |

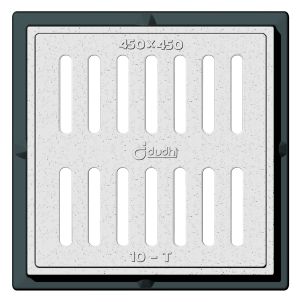

| Category | Description |

|

|---|---|---|

| A | Load 2.5T (Point Load/Wheel load 0.8T) | Low |

| B | Load 5T (Point Load/Wheel load 2.5T) | Very Low |

| C | Load 10.0T (Point Load/Wheel load 3.0T) | Low |

| D | Load 20.0T (Point Load/Wheel load 5.0T) | Heavy |

| E | Load 40.0T (Point Load/Wheel load 11.5T) | Manually Compress |

| Description | Dudhi Manhole Cover |

|---|---|

| Longitudinal strength | 250-600 Mpa |

| Compressive strength | 300-600 Mpa |

| Stretch modulus | 25-35 Gpa |

| Break elongation ratio | 1.3-10.0% |

| Bending strength | 700-1400 Mpa |

| Poisson-ratio | 0.35 |

| Relative density | 1.11-1.15 |

| Water-absorvation (24h) | 10-30 mg |

| General Application (Working Temperature) | -40°C~120°C |

Features