Block Adhesive

Block Adhesive

Dudhi Block Adhesive is polymer modified adhesive suitable for block work in interior and exterior situations. It is designed for thin bed fixing of blocks of various kinds including light weight blocks. It contains selected graded dry sand, grey cement and imported polymers to improve workability, water retention, durability and adhesion.

Specification

| Parameter | Dudhi Block Adhesive |

|---|---|

| Pot Life | 60 -120 minutes |

| Hard Dry | 20 — 25 hrs |

| Appearance | Grey Powder |

| Curing | No additional water curing is required |

| Tensile Adhesion Strength After 28 Days | 0.5 — 1 N/mm² |

| Compressive Strength after 28 Days | 10 -15 N/mm² |

| Coverage | 4-5 sq.tt./kg for 3mm thickness |

| Average Thickness | 3 mm For Block Size 600X200X150 mm |

| Water Demand | 25 - 30% |

| Ingredients | Cement+ Graded Sand+ Additives+ Polymer |

| Shelf Life (Months) | 6 Months in sealed bags. (Store in cool and dry place) |

| Packing Size | 20 Kg & 40 Kg |

| Density | 1400 - 1500 kg/m³ |

| Standard | Complies the specification of IS-15477:2004 |

Comparison Chart

| Dudhi Block Adhesive | Conventional Mortar |

|---|---|

| Approx. Rs. 3.5/sq. ft. | Cement (0.5 kg @ Rs 300 per bag) = Rs. 3 + Sand (0.045cft @ Rs per cft) = Rs. 1.80 Total = Rs. 4.8 per sq. ft. |

| Fast Application | Not Possible |

| Plastering possible after 24 hours | Minimum 7 days curing required |

| Consistent quality due to computerised mixing and tested raw material | Manual mixing and not possible to test every batch |

| High bond strength (almost 5 times more than conventional mortar) | Not possible due to difference in properties of blocks and mortar |

| Negligible shrinkage cracks | More shrinkage cracks |

| Easy handling and storage | Difficult to keep stock of different components and high wastage |

Consumption of Material

- Consumption Per mm/ Per Sq. Ft.- 0.100 kg

- Coverage 13mm Thickness 30sq-ft/40 kg bag, 19 sq-ft/25 kg bag

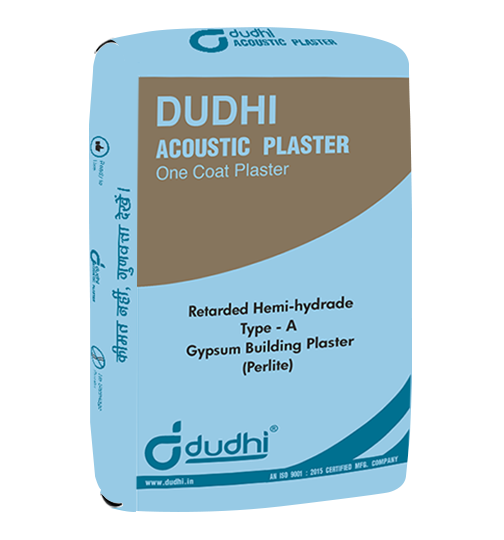

Features & Benefits

- Eliminates two-step process of Sand Cement Plaster and POP punning

- Doesn’t require water curing

- No shrinkage cracks

- Non-combustible (when tested in accordance with BS: 476: part 4:1970), therefore a good form of

thermal protection to the building structure. - Use of light weight aggregates in the plaster mix help to improve Low thermal conductivity (0.25

W/m-K) as compared to Sand Cement Plaster (0.72 W/m-K) ** keeps room cooler in summer and

warmer in winter; saving in energy cost - The water absorption as per DIN EN 520 is less < 10%

- Excellent Capillary

- Water absorption coefficient test method —- BS EN 1015-18.

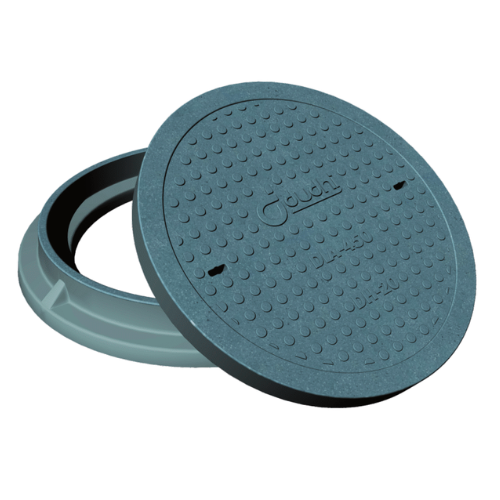

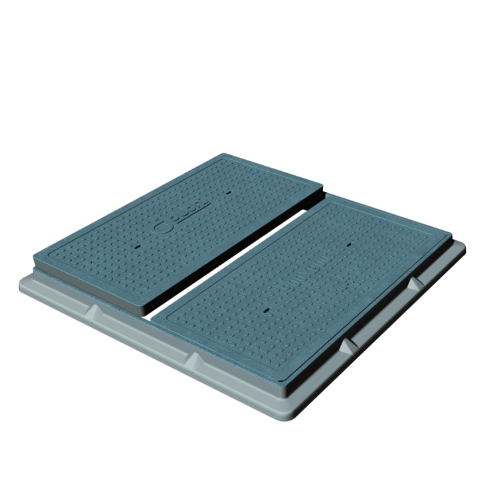

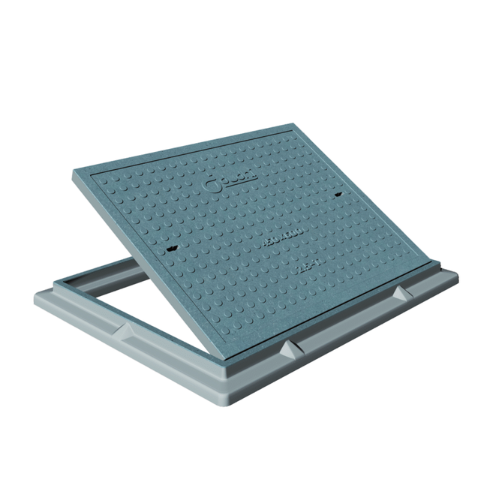

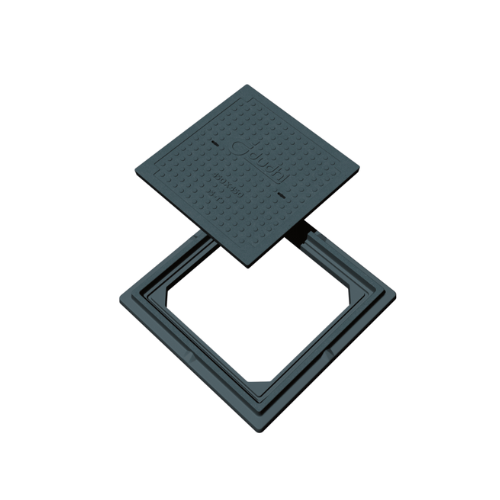

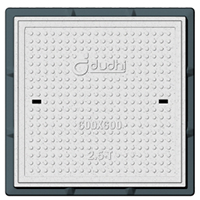

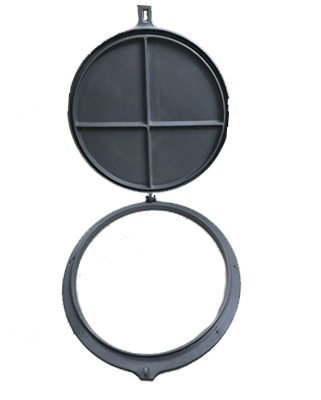

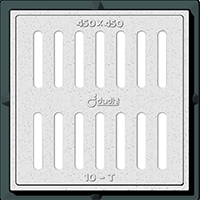

Available Sizes

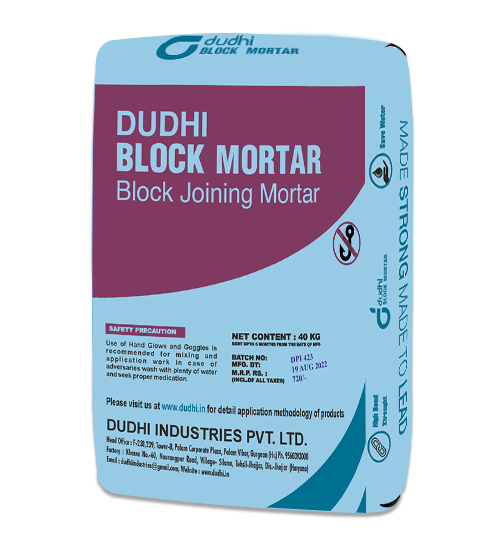

Identification & Packing

Dudhi Gypsum (Brick Solution) (Moisture Resistant) is packed in PP bags. The outer layer of the bag is printed with the product image, batch number, date of manufacturing, correspondence address and application instructions.

Backed by Superior Service

- Technical service team offers regular site training to use tools and technology to improve

productivity. - Intermediate site inspections and feedback.

- Recommend trained application Team.

- Largely distributed manufacturing capacity.

Testing Standards

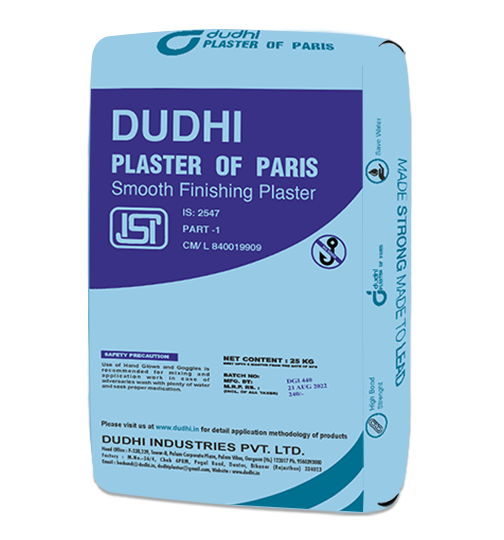

- Confirms to IS 2547 (Part |) — 1976 for physical & chemical characteristics

- Confirms to IS 2547 (Part Il) — 1976 for physical characteristics

- HSN Code : 252020, GST : 5%

Certification:

- Conforms and Certified to IS 2547: Part 1 and 2 of “The Bureau of Indian Standard” as per

licence number CML-8400019909 - Meets standards of Green Pro certification and qualifies as green product.

Storage & Handling

Dudhi Gypsum (Brick Solution) (Moisture Resistant) is supplied in 4OKg bags. The dimensions of the bag ensure that a well-filled appearance is presented when filled and the bags can be stacked on a pallet in a stable and well-stacked array. Bags should be stored dry, as absorption of water shortens the setting time, causes set lumps to (*) form in the bags and may reduce the strength of the set plasterwork. No hooks or any sharp tools should be used to carry bags from one location to another.

Application Procedure

Surface Preparation

- The surface of masonry units should be slightly wet prior to application of Dudhi Block Adhesive.

- The masonry units should be clean, with no loose particles or dust for better bonding.

Mixing

- It is very important that Dudhi Block Adhesive is mixed with water thoroughly before use. It is advisable to use a mechanical stirrer for uniform mixing to save time, labour and for maximum workability effectiveness.

- Use a clean vessel/bucket which does not have any hole or cut and add some water in the empty vessel to ensure no powder gets stuck at the bottom of the vessel and put required quantity of Dudhi Block Adhesive.

- Mixing Ratio – depending on the thickness of the product to be applied, add approximately 25-30% of the clean potable water. Water is added in stages to get a smooth, uniform, workable mix. Allow ample time for initial mixing.

- Ensure that no powder is left unmixed at the bottom of the vessel.

- The jointing mortar is now ready for application.

Application Methodology

- Layout the wall where Dudhi Block Adhesive is to be used and mark openings like door, windows or any architectural appurtenances.

- Apply a thin uniform layer of Dudhi Block Adhesive, 3-4 mm thick, on the clean & leveled surface of masonry units using proper trowel.

- Place the next course of masonry units on the evenly laid jointing mortar bed in proper line & level. Each masonry unit should be properly bedded and set in position by gently pressing with the handle of a trowel.

- After placing the first unit, apply Dudhi Block Adhesive of same thickness on both the sides of the unit, keeping continuous check for the line & level.

- Inside face of the masonry unit should be buttered with mortar before the next unit is laid and pressed against it especially in case of bricks.

- Clean the excess material immediately, if any. Continue the procedure for the entire masonry work.

Precautions During Usage

- Though Dudhi Block Adhesive contains no toxic material, still care should be taken to avoid dust inhalation while mixing and handling. In case of contact with eyes or face, wash with plenty of clean water.

- Keep it in a dry place and out of reach of children.

- Persons who are allergic to cement should take proper precautions before use.

Features