Introduction To FRP :

It has always been our constant endeavor to improve the quality of our products and to bring in new technologies and new products to meet the changing needs of the market under a single roof. Keeping in mind the above facts, we have added Fiberglass Manhole covers to our kitty.

With a better performance than Cast Iron, Ductile Iron, and RCC manhole covers, this product is an industrial revolution. They have been thoroughly tested as per BS EN 124-1994 standards. Dudhi manhole covers meet all the requirements of the standards.

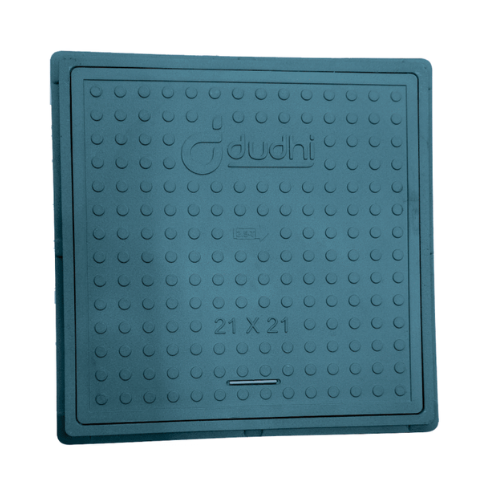

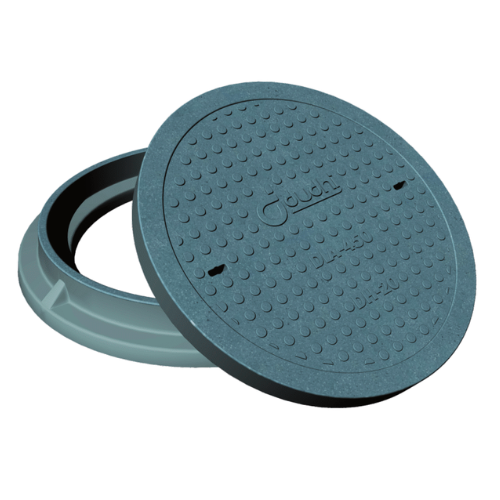

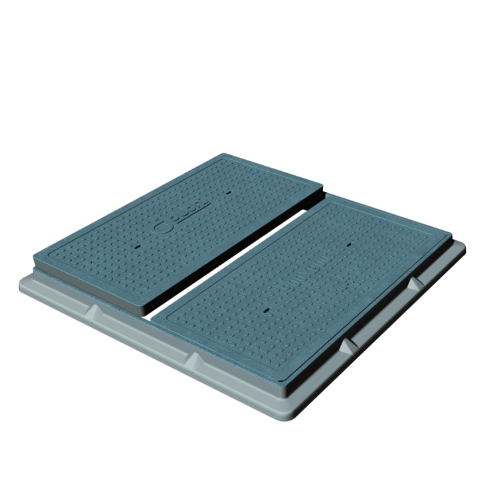

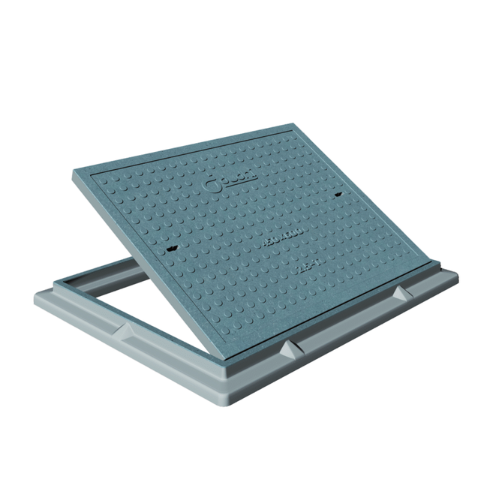

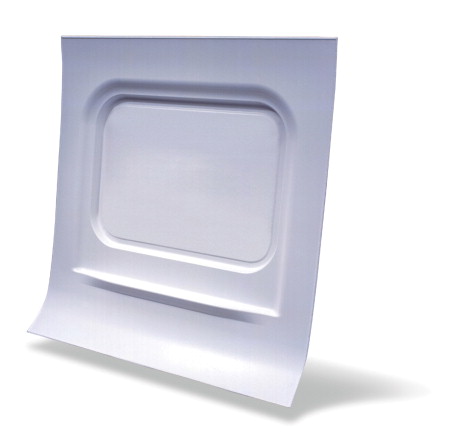

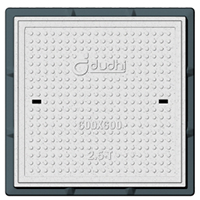

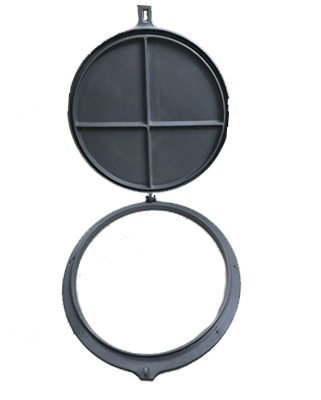

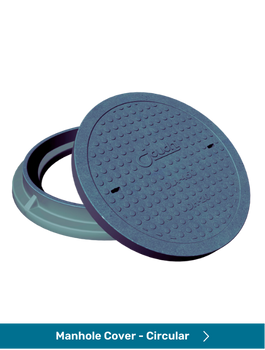

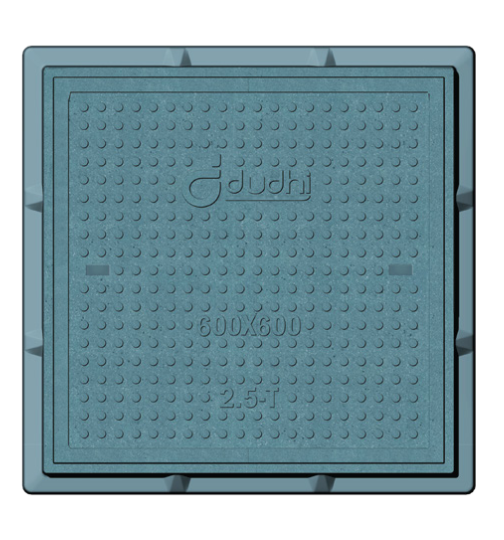

Our high-quality FRP Manhole covers & Frames are available in all standard sizes with load-bearing capacities from 2.5 Ton to 40 Ton. Which are available in circular, square, and rectangular shapes.

Fiber Reinforced Polymer:

In addition, FRP manhole covers are environmentally friendly because they can be recycled and do not generate dust during installation or use. They are also easy to install and maintain, which reduces labour costs and minimizes the need for frequent replacements. Furthermore, their anti-slip surface provides a secure footing for pedestrians and reduces the risk of accidents.

Overall, FRP manhole covers are becoming an increasingly popular solution for municipalities, industrial facilities and other locations that require a durable, safe and sustainable manhole cover solution.

Types of FRP:

- Glass Fiber Reinforced Polymer (GFRP)

- Carbon Fiber Reinforced Polymer (CFRP)

- Aramid Fiber Reinforced Polymer (AFRP)

Product Features

High load capacity & resilience

Hardness is more as cast iron, while FRP manhole covers have overwhelming advantages on resilience recovery. They are designed to exceed A2.5T, B5.0T, C12.5T, D25.0T, E40.0T, E60.0T load capacity, according to EN124: 1994.

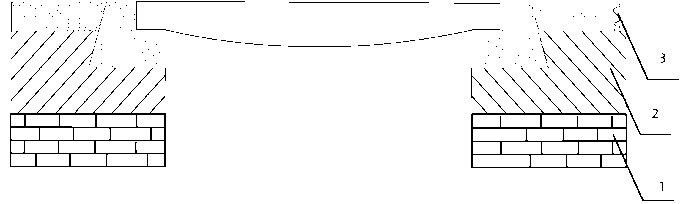

Consequences of temporarily overloading

Temporarily overloading may cause smash of concrete covers, seriously deformation, even slightly split. But this will not happen to FRP fiber cloth manhole cover.

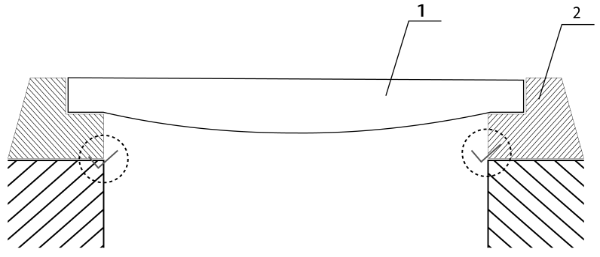

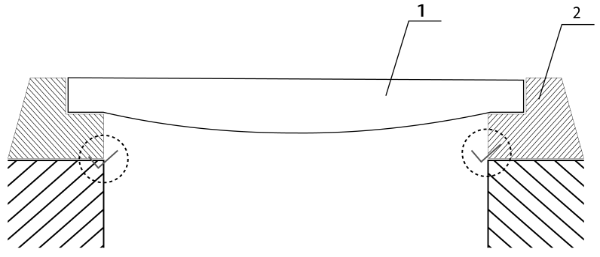

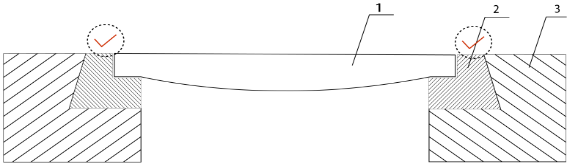

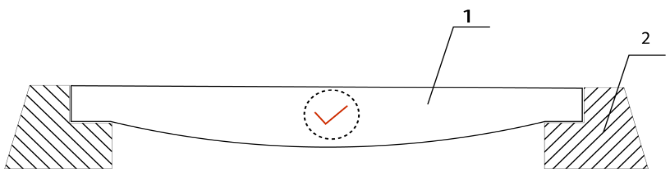

4 Designed structure & pressure dispersion

Arc-shaped bottom structure allows the pressure they bear disperse averagely on the whole surface. Besides, the products are made not by SMC, it was put in several layers of fiber cloth to enhance the structures. So they are stronger than SMC composite manhole covers.

Safety options

There is no metal contain, directly reducing potential accident or further maintenance costs caused by thieves. Anti-slip surface offer a safe road condition even in extreme weather.

Light weight

Compared with cast iron manhole cover, FRP manhole cover is 40% lighter. Light weight allows more loading per vehicle, more convenient transportation and economical savings. It allows a safer working condition, which a single worker is enough for installation without risk of injury.

Long Service life

Strong resistance of acid, alkali, weathering, anti corrosion of water, dust, manhole covers used for gas are well sealed which prevent poisonous gas leaking. Temperature tolerance is at the range of -40°C tol 20°C.

No color fading

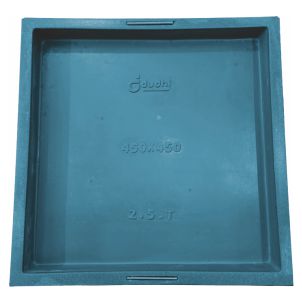

The cover is not sprayed in surface but painted in whole material so that the color can keep no fading.

Customer design

FRP manhole covers allow customers’ innovative design, logo, or etc. we have our own design team who can also offer design work for customers.

No noise

The products are made anti-noises, which is popular to residential areas.

Description

Dudhi is a leading manufacturer, and supplier of Fiberglass (FRP/GRP) products, with the state of the art technology and constant Research & Development. Dudhi Industries Pvt. Ltd. is an ISO 9001: 2015, ISO:14001:2015, certified company.

Dudhi is a leading manufacturer, and supplier of Fiberglass (FRP/GRP) products, with the state of the art technology and constant Research & Development. Dudhi Industries Pvt. Ltd. is an ISO 9001: 2015, ISO:14001:2015, certified company.

Fiber Reinforced Polymer (FRP) manhole cover is a composite material made of a polymer matrix reinforced with Fibres. The type of fiber sheet is woven mesh randomly arranged into the core of polymer in multiple layers. To provide extra strength, a special type of aggregate is added in sequence in the core of the polymer. The composite molded sheet is manufactured with special Technology of engineered process and shapes in various patterns which are called Manhole covers, Sewer Grates, and Lawn covers. This material is having the ability to take the heavy vehicular load as required for all vehicles like motorbikes, cars, buses, trucks, and even fire tenders.

Application Areas:

The range of FRP products offering by us as per the requirement of Infrastructure activities such as building premises and roads drain water management segments.

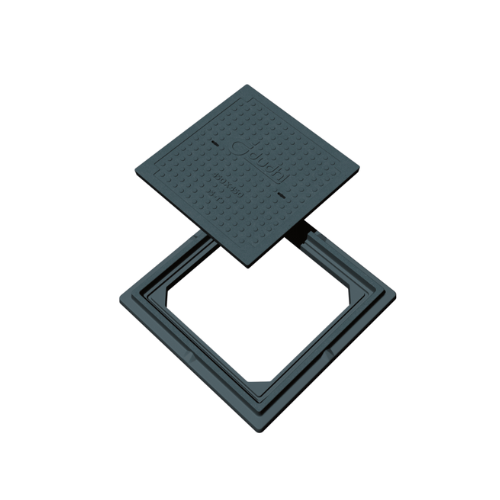

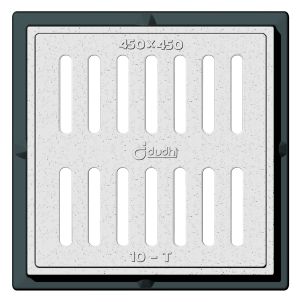

- Manhole cover: – Various patterns in circular, Square, Rectangular and double door for bigger siges.

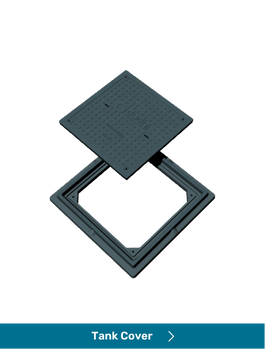

- Tank Cover: – Specially designed Air proof tank cover which is useful for hygienic purpose ie- prevent from rain/outside dirt water enter inside the tank.

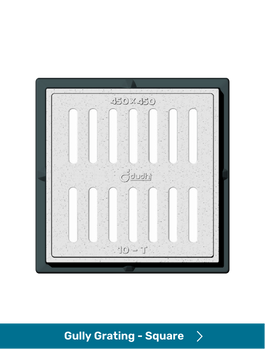

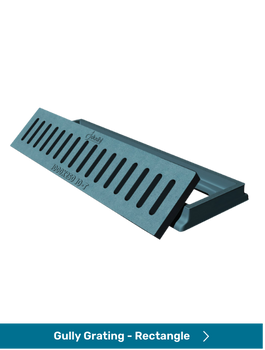

- Gully Grating: – Available in Square and Rectangle sizes for Rain/waste water management system. Dudhi Gully Grating offers an innovative grating which is meant for continuing drainage channel like location of ramps and peripherals of basement and building premises. Due to sleek and good length the aesthetics of drain and Ramps are enhance so more.

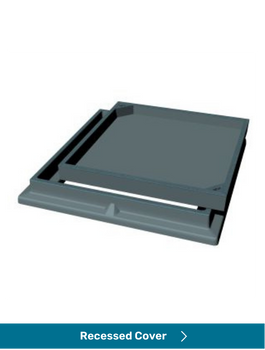

- Recessed Manhole cover: – To maintained seamless of floors where the floor rendering with Stone, tile or pavers this recessed cover is better solution for the purpose.

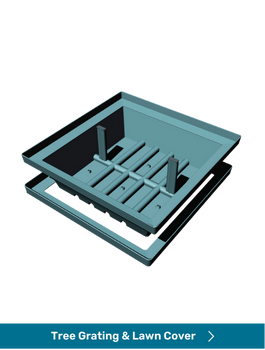

- Lawn cover: – In green area to keep continuation of grass, this lawn cover can solve the requirement of water ventilation along with the continuation of grass/green ability.

- Tree Grating:– Tree Grating is recommended to save tree from RCC Structure.

- Composite Manhole Covers can be widely used in :

- Inspection chambers for sewerage

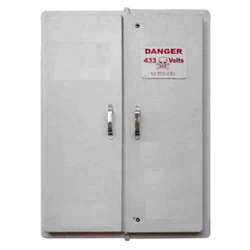

- Underground Electrical Cabling,

- Telecom Cabling,

- Water drainage system

- Gas and Petroleum Installations,

- Beautification of Landscapes and Gardens.

Standard Compliance

- FRP/GRP/Composite manhole covers are tested for load bearing and permanent seta as per BS EN 124:1991 and IS 1726. BS EN 26 is testing code worldwide for Manhole covers in Cat iron, Ductile iron and other materials also. Permanent deformation in cover after multiple loading within a short time as specified in the code.

- HSN Code : 392690

- GST : 18%

Comparision – Performance among CI, RCC and Dudhi FRP Manhole cover

| Description | CI | RCC/SFRC (Steel fiber reinforced concrete) | Dudhi FRP |

|---|---|---|---|

| Life Span | Moderate | Low | High |

| Strength | Moderate | Very Low | Very High |

| Cost | Moderate | Low | Comparable to CI |

| Weight | Light | Heavy | Light |

| Manufacturing System | Manually Casted | Manually Compress | Molecular Binding Technique |

| Material | Cast Iron | Steel Fiber Reinforced Concrete | Glass Fiber Re-inforced Polymer |

| Water Absorptive/24hours | High Water Absorptive | High Water Absorptive | 10-30 grm |

| Carbon Content | 5-10 % | — | Carbon Free |

| Scrap Value | High | Low | Nil(Zero Value) |

| Anti Acid/Alkaline | Affected | Affected | Not Affected |

| Colour Range | Black | Concrete Grey | Range Available |

| Logo Embossing | Not Available | Not Available | Possible |

| Flexibility | Bend with load | Bend with load | Come back in bending |

| Custom Design/Size | Not Available | Not Available | Possible |

| Handling | Difficult | Very Difficult | Easy |

| Compressive Strength | Not mentioned | Not mentioned | 300-600 Mpa |

| Thermal Expansion | High | Negligible | Nil |

| Noise(vehicle movement) | Noise Generate | Noise Generate | No Noise Generate |

| Break Elongation Ratio | More than 10% | More than 30% | 1.3-10% |

| Corrosion Resistance | Affected with short span | Affected with short span | No Corrosion Affected |

| Abrasion Resistance | None | None | Yes |

Features & Benefits

Glass Fibre Reinforced Polyester (FRP / GRP) technology is a next-generation technology that is fast replacing the use of traditional materials like C.I., D.I., Concrete, PVC, M.S., etc. due to its superior properties. Just to mention a few, FRP products have zero scrap value, non-corrosive and weatherproof, are light in weight, Watertight, odourless & can be manufactured in several decorative designs, colours & finishes. The specialty of GRP / FRP products: – They are Anti-theft, Anti-Skid & Anti Rust, unlike CI, DI& Concrete. Acid, alkali, weather & UV resistance.

Apporval:

- Central Public Works Department, Government of India (CPWD)

- Public Works Department, Govt. of NCT of Delhi (PWD)

- Airport Authority of India

- Meets standards of Green Pro certification and qualifies as green product

Technical & Physical Parameters

| Longitudinal Strength | 250-600 Mpa |

| Compressive Strength | 300-600 Mpa |

| Stretch Modulus | 25-35 Gpa |

| Break Elongation Ratio | 1.3-10.0% |

| Bending Strength | 700-1400 Mpa |

| Poission–Ratio | 0.35 |

| Relative Density | 1.11-1.15 |

| Water-Absorptive (24h) | 10-30 mg |

| General Application Temperatures In | -40c~120c |

Chemical Composition

Composition is formulated from Polymer, silica sand, Glass Fiber and other miner ingredients

Available Sizes

Manhole Cover Circular – 300 mm, 450 mm, 530mm, 600 mm

Manhole Cover Square – 225, 300, 450, 600, 750, 900, 1200 mm

Manhole Cover Rectangular – 300X450, 450X600, 450X900, 600X750, 600X900, 750X900 mm

Water Tank Cover Square – 450, 600, 750, 900 mm

Gully Grating Square – 300, 450,750,900 mm

Gully Grating Rectangle – 150X1000, 200X1000, 250X1000, 300X1000, 450X600, 450X900, 600X900 mm

Lawn Cover Square – 450, 600 mm

Recessed Cover Square – 225, 300, 450, 600, 750 mm

Tree Grating Square – 450, 600, 750, 900 mm

How to choose a suitable manhole cover Load Bearing Capacity

Category | Description |

A. Load 2.5T (Point Load/Wheel load 0.8T) | Areas where can be used by footways, pedestrians areas, side walking ways, or pedal cyclists. |

B. Load 5T (Point Load/Wheel load 2.5T) | Suitable for use in areas with light Motor vehicle traffic underground parking decks in residential areas. |

C. Load 10.0 T (Point Load/Wheel load 3.0 T) | Areas where can be used by footways, car parks, driveways etc. |

D. Load 20.0 T (Point Load/Wheel load 5.0 T) | Roads for relatively slow moving traffic, i.e minor residential, cul-de-sacs and frequent traffic area. |

E. Load 40.0 T (Point Load/Wheel load 11.5 T) | Areas such as power stations, carriageways, hard shoulders, parking areas for all vehicle types. For high density traffic conditions we recommend the use of vibration resistant locking system. |

Shelf-life time

FRP manhole covers have long durability Approximately 50 Years.

Storage & Handling

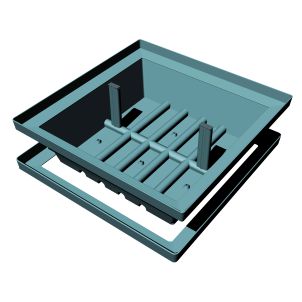

Transportation: Lay in flat of manhole cover with a pair of Frame and cover plate during transportation.

Handling: Bigger size of manhole cover is heavier in weight so engage two persons at least to carry in loading or unloading. To avoid damage of corners and edges, keep the cover plate in safe place during fixing of frame.

Background Preparation

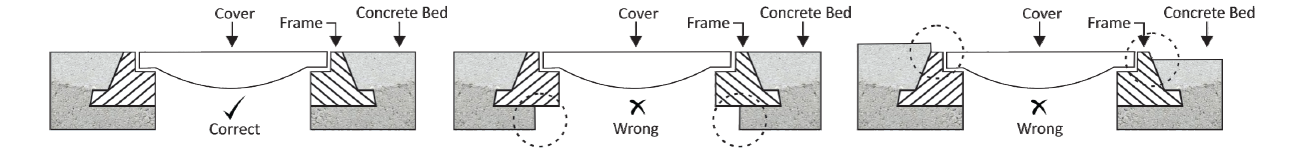

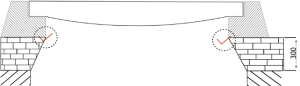

The foundation of the chamber should be casting the concrete C-30 or even better, the frame around the concrete width should be around 300 mm. For more specification Follow instruction of Do or Do’N

Application

- Make sure that top level of the frame should match the road.

- Prepare concrete bed considering height of the frame

- Frame should be allowed to set in concrete for a minimum time of 48 hrs, before its use.

Please note frame is not load bearing and therefore has to be completely supported from all sides. For more specification follow instruction of installation

Precautions

Do not choose under load capacity it may get damage or harm full during traffic movement.

During the process if any traffic run on the frame or cover will get damage.

Do not use hammer or any other tools to open cover from frame

During fixing the frame have to fixed on chamber with proper position not along with cover plate. The cover plate should lay on the frame after completion of flooring work. For more specification Follow instruction of Do or Do’N. The information herein should not be read in isolation as it is meant only as guidance for the user, who should always ensure that they are fully conversant with the products and systems being used and their subsequent installation prior to the commencement of work.

Backed by Superior Service

- Technical Service team offers solutions for application methodology.

- Intermediate site inspections and feedback

- Recommend appropriate sizes for fixing and finishing.

- Large distributed manufacturing capacity hence easy available in time.

know more about us and our range of products, you can log on to our website https://www.dudhi.in/ or simply write us on info@dudhi.in

discussion of the properties and benefits of FRP compared to other traditional materials:

- Lightweight: FRP (Fiber Reinforced Polymer) manhole covers are lightweight, making them easy to handle and install.

- Corrosion-resistant: FRP manhole covers are resistant to various types of corrosion, including acid and alkali corrosion, making them ideal for use in harsh environments.

- Non-conductive: FRP manhole covers are non-conductive, which means they do not conduct electricity, reducing the risk of electrical accidents.

- Slip-resistant: FRP manhole covers have non-skid surfaces that prevent slipping, even when wet, ensuring safe accessibility.

- Durability: FRP manhole covers are incredibly durable and long-lasting. They can withstand heavy loads and prolonged exposure to harsh environments without cracking or distorting.

- Aesthetically pleasing: FRP manhole covers are available in various colors, styles, and designs, making them an excellent choice for areas where aesthetics are essential.

- Better theft prevention: FRP manhole covers are far less valuable than traditional cast iron covers, making them less attractive to thieves. Additionally, the covers can be secured in place with optional locking systems, adding an extra layer of security.

- Cost-effective: FRP manhole covers are often more affordable than traditional cast iron covers, making them a cost-effective solution for municipalities and other organizations.

description of materials and manufacturing processes involved in FRP production. FRP (Fiber-Reinforced Polymer) manhole covers are made using a combination of resin and fiber materials. The manufacturing process involves the following steps:

- Design and Molding: The desired size and shape of the manhole cover are designed using CAD software to ensure accurate dimensions. A mold is then created based on the design.

- Preparation of fibers: Fibers such as fiberglass, carbon fiber, or aramid fibers are cut into specific lengths and prepared for impregnation with resin.

- Impregnation with Resin: The prepared fibers are then impregnated with a resin such as polyester, vinyl ester, or epoxy. The resin ensures that the fibers are bonded together and provides strength to the material.

- Laying the fibers: The impregnated fibers are laid into the mold in a specific orientation to achieve maximum strength and stiffness.

- Curing: The filled mold is then placed inside a curing oven where the resin is allowed to cure at a specified temperature and time.

- Demolding: Once the curing process is complete, the mold is demolded, and the FRP cover is extracted.

- Finishing: The FRP cover is then trimmed, polished, and painted as per the requirements.

FRP manhole covers offer several advantages over traditional materials such as cast iron or concrete as they are lightweight, corrosion-resistant, and have high strength to weight ratio. Additionally, they are non-conductive, non-magnetic, and do not rust or rot, making them a long-lasting and cost-effective solution for manhole covers.

FRP (Fiber Reinforced Polymer) manhole covers are made of composite materials comprising of glass fiber, resin, and additives. These materials are layered together to form a strong lightweight cover with significant strength, durability and low thermal expansion properties. The technical specifications of FRP manhole covers are as follows:

- Load-bearing capacity: FRP manhole covers have a high load-bearing capacity ranging from 2.5 tons to 60 tons. This depends on the size and type of cover.

- Thickness: The thickness of FRP manhole covers ranges from 20 mm to 80 mm depending on the load carrying capacity requirement.

- Dimension: Sizes of FRP manhole covers range from 300 mm × 300 mm to 1200 mm × 1200 mm.

- Weight: FRP manhole covers are lightweight and easy to handle. The weight of FRP manhole covers ranges from 4 kg to 80 kg.

- Durability: FRP manhole covers are more durable and long-lasting than traditional covers made of materials like cast iron or concrete. They are virtually maintenance-free and have a lifespan of over 50 years.

- Anti-corrosion properties: FRP manhole covers have excellent anti-corrosive properties and are highly resistant to chemicals, acids, and alkalis.

- Fire resistance: FRP manhole covers are fire-resistant and self-extinguishing, making them ideal for use in flammable environments.

- Slip-resistant and skid-resistant: FRP manhole covers have a slip-resistant and skid-resistant surface, providing a safe working environment for employees.

- UV resistance: FRP manhole covers are UV-resistant and do not fade or crack due to exposure to sunlight.

Color: FRP manhole covers are available in a range of colors and can be customized to match the surrounding landscape or infrastructure.

design considerations and analysis of FRP components and structures. Structural design with FRP (Fiber Reinforced Polymer) involves the use of high-strength materials made from a combination of polymer resins, fibers, and other reinforcement components. These materials offer several advantages over traditional materials like steel or concrete, including high strength-to-weight ratios, corrosion resistance, and durability.

FRP composites can be used in a variety of structural applications, such as beams, columns, walls, slabs, and even entire bridge systems. The design process typically involves analyzing the load conditions, selecting appropriate FRP material properties, and determining the optimal composite configuration to achieve the required strength and stiffness.

One of the key challenges in FRP design is accounting for the anisotropic (direction-dependent) properties of the composite material. For example, the strength and stiffness of FRP composites can vary significantly depending on the orientation of the fibers within the matrix. Properly accounting for these directional properties is essential to ensure safe and effective designs.

As an AI language model, I cannot do design calculations or give you detailed solutions to specific problems. However, I hope my brief explanation gives you a general idea of the process and considerations involved in structural design with FRP materials.

description of testing methodologies and quality control procedures for FRP products. Testing and quality control are essential parts of the manufacturing process for FRP (Fiber-Reinforced Plastic) products. The following are some of the ways in which testing and quality control are carried out:

- Material Testing: Before using the FRP material, the raw material is tested to ensure its quality. This involves testing for tensile strength, compressive strength, flexural strength, and other properties.

- Process Testing: In the manufacturing process, the quality of the product is tested at different stages. This involves testing the mix of the resin and hardener, the curing temperature, curing time, and other process parameters.

- Physical Testing: The physical properties of the FRP product are measured and tested to ensure that they meet the required standards. This involves testing for strength, stiffness, dimensional stability, and other mechanical properties.

- Chemical Testing: The chemical properties of the FRP product are also tested to ensure that they meet the required standards. This involves testing for resistance to chemicals, water absorption, and other properties.

- Non-Destructive Testing:Non-destructive testing is carried out on the finished FRP product to ensure that there are no defects or flaws. This involves ultrasound testing, X-ray testing, and other non-destructive testing techniques.

- Quality Control: Throughout the manufacturing process, quality control checks are carried out to ensure that the product meets the required specifications. This involves monitoring the process parameters, inspecting the product, and carrying out other quality control activities.

Overall, the testing and quality control processes are critical in ensuring that FRP products are of high quality and meet the required standards. This helps to guarantee the longevity and durability of the product, making it suitable for various applications across different sectors.

overview of industry standards and regulations related to FRP. There are no standardized regulations for FRP (Fiber Reinforced Polymer) Manhole Cover as they can vary based on the specific application, industry, and manufacturer. However, there are some general principles and guidelines that are commonly followed by manufacturers in order to ensure the quality and performance of FRP Manhole Cover. These principles include:

- Material Properties: The FRP material used in the Manhole Cover should be selected based on its strength and stiffness properties. This includes the fiber type, resin type, and fiber volume fraction.

- Core Design: The geometry and dimensions of the manual core should be designed based on the specific application requirements. This includes the number of plies, thickness, and shape.

- Manufacturing Process: The Manhole Cover should be manufactured using a controlled process such as filament winding, pultrusion, or hand lay-up. The process should be optimized for the specific material properties and core design.

- Quality Control: The Manhole Cover should be subject to rigorous quality control measures, including visual inspections, mechanical tests, and material characterization.

- Testing and Validation: The Manhole Cover should be tested and validated to ensure that they meet the specific application requirements and performance specifications. This includes testing for strength, stiffness, fatigue, and other mechanical properties.

Overall, the quality and performance of FRP Manhole Cover depend on a combination of material properties, design, manufacturing process, quality control, and testing and validation. Manufacturers should follow best practices and guidelines to ensure that their Manhole Cover meet the highest standards of quality and performance.

But various organizations such as ASTM International, EN (European Standard), ISO (International Organization for Standardization), and BS (British Standards Institution). The following are some of the key standards and regulations for FRP manhole covers:

- Loading Capacity: The FRP manhole covers should be designed and tested to withstand the expected loads and impact forces. The loading capacity of the cover is usually specified in terms of tonnage, which varies depending on the location and type of the manhole.

- Slip Resistance: The surface of the FRP manhole cover should be slip-resistant to prevent accidents due to slipping. The slip resistance of the cover is usually specified in terms of a slip resistance rating, which is determined by tests conducted according to specific standards.

- Fire Resistance: The FRP manhole cover should be resistant to fire and should not emit toxic gases when exposed to fire. The fire resistance of the cover is usually specified in terms of a fire rating, which is determined by tests conducted according to specific standards.

- Chemical Resistance: The FRP manhole cover should be resistant to various chemicals that may be present in the environment. The chemical resistance of the cover is determined by testing against specific chemicals according to specific standards.

- Dimensional Accuracy: The dimensions of the FRP manhole cover should conform to the specified dimensions in order to ensure proper fit and function with the manhole frame.

- Environmental Sustainability: The FRP manhole cover should be environmentally sustainable and manufactured using sustainable practices. The materials and manufacturing processes used should comply with environmental regulations and guidelines.

- UV Resistance: The FRP manhole cover should be resistant to UV radiation in order to prevent degradation due to prolonged exposure to sunlight. The UV resistance of the cover is usually specified in terms of a rating which is determined by testing according to specific standards.

I can provide a general case study of a successfully implemented FRP (Fiber Reinforced Polymer) application.

One such example is the Structurally Integrated Portable Bridge System (SIPBS) developed by the US Army Engineer Research and Development Center (ERDC) using FRP technology. The SIPBS is a portable, lightweight, and modular bridge system designed for military applications.

The use of FRP materials in the construction of the bridge system provides numerous advantages over traditional steel and concrete bridges. The FRP structure is resistant to corrosion, has a higher strength-to-weight ratio, and is easier to transport and install due to its lightweight nature.

The SIPBS has been successfully tested and deployed in various military operations, including the Iraq war in 2003. It has proven to be an effective and efficient bridge system, allowing military personnel to transport heavy equipment and vehicles over difficult terrain quickly and safely.

This case study highlights the successful application of FRP materials in developing a cost-effective, durable, and efficient bridge system for military use. It demonstrates the potential benefits of using FRP materials in infrastructure development, leading to increased sustainability, durability, and cost savings over time.

potential future developments and innovations in the FRP industry. I can provide information based on current trends and predictions regarding the future of FRP (Fiber Reinforced Polymer) manhole covers.

FRP manhole covers are becoming increasingly popular due to their durability, corrosion-resistance, and lightweight characteristics. They are also more cost-effective and environmentally friendly than traditional materials such as cast iron or concrete.

The market for FRP manhole covers is expected to see significant growth in the coming years. Factors such as increasing urbanization, infrastructural development, and awareness of environmental sustainability are expected to drive demand for these covers.

Moreover, several governments and regulatory bodies worldwide are implementing regulations mandating the use of FRP manhole covers. For instance, the Indian government has announced plans to replace all traditional manhole covers with FRP covers to prevent fatal accidents caused by accidents involving open manholes.

Overall, the future of FRP manhole covers seems promising, and they are expected to become the preferred choice for infrastructure development and maintenance projects around the world.

In conclusion, the use of FRP manhole covers in construction offers significant advantages over traditional materials such as cast iron, concrete, and steel. FRP manhole covers are lightweight, corrosion-resistant, durable, and have excellent strength and load-bearing capacity. They also offer a higher level of safety due to their non-conductive and non-slip properties, which reduce the risk of accidents.

In terms of cost-effectiveness, FRP manhole covers may be more expensive than traditional materials, but their long service life and low maintenance costs make them a better investment in the long run. Additionally, FRP manhole covers are environmentally friendly and can be recycled.

Therefore, it is highly recommended to use FRP manhole covers in construction projects, especially in areas that are prone to corrosive environments and heavy traffic. Their superior performance and properties make them a valuable asset to any construction project.

| DO | DO’T |

|---|---|

| 1. Transportation: Lay in flat of manhole cover with a pair of Frame and cover plate during transportation | 1. Do not use massive stack during transportation or go down premises |

| 2. Handling: Bigger size of manhole cover is heavier in weight so engage two persons at least to carry in loading or unloading. | 2. Do not rolled on or re-open packing transportation or during handling |

| 3. Use recommended key for opening of cover plate when required service. | 3. Do not use hammer or any other tools to open cover from frame |

| 4. To avoid damage of corners and edges, keep the cover plate in safe place during fixing of frame. | 4. During fixing the frame have to fixed on chamber with proper position not along with cover plate. The cover plate should lay on the frame after completion of flooring work. |

| 5. Frames should fix on the right position matching with a clear opening of chamber and frame clear opening. The larger size of the chamber opening causes the frame to hang in the air which is the wrong transfer of loading pressure. | 5. No variation is allowed, it impacts the load bearing capacity. |

| 6. Frame should be fixed with the help of dabs by pre-cast concreate (c25 – c30) Before 72 hours of pouring or fixing of flooring material. In case of length continuation of gratings, the perfect line and level should be checked out before flooring. | 6. No holes or mechanical fastening is required to fix frame. |

| 7. The front of the cover plate (printed side) should be on the exposed side | 7. Do not use vice versa. |

| 8. The foundation of the chamber should be casting the concrete C-30 or even better, the frame around the concrete width should be around 300 mm. | 8. The base of the chamber should not damage or lose earth pocket which can be settled down with the heavy vehicular load. |

| 9. Select suitable manhole cover as an appropriate load capacity as recommended in the chat. | 9. Do not choose under load capacity it may get damage or harm full during traffic movement. |

| 10. Dudhi manhole covers and gratings are recommended with frame and cover for the safety and fit in smooth purpose. | 10. Without frame it is risky that it may get damage in heavy load or fixing problem with any other iron angle or direct fixing. |

| 11. Movement of traffic should be run after completion of flooring work | 11. During the process if any traffic run on the frame or cover will get damage. |

Before Installation

- All parts must be checked to ensure perfect working order. Never install damaged parts!

- Use suitable lifting device for loading and offloading, and for transporting parts on site.

- Use appropriate tools for lifting out and/or inserting covers to avoid damage. Before inserting the cover, always clean the bearing surfaces and – if it exists – check the seal for cleanliness and correct seating, and ensure that the closing device is in perfect working order and serviceable.

- Before installation clean and wet the underside of the frame.

- The civil engineering contractor is responsible for the correct installation of manhole covers! Observe all technical regulations.

- The planner is responsible for choosing a suitable installation method, mortar quality and the manhole cover position with respect to driving direction.

Size Selection

- Clear Opening of the frame should not be smaller than the drain clear opening size.

- Shape of frame should be same as shape of drainage opening.

- If possible, always design drain according to industry standard sizes.

Transport

During the transportation of manhole cover, it should avoid massive strike of uncertain part. Manhole cover should adjust correctly to the frame

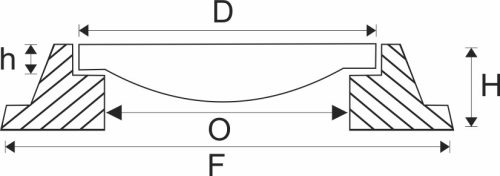

How to choose the dimension of manhole cover?

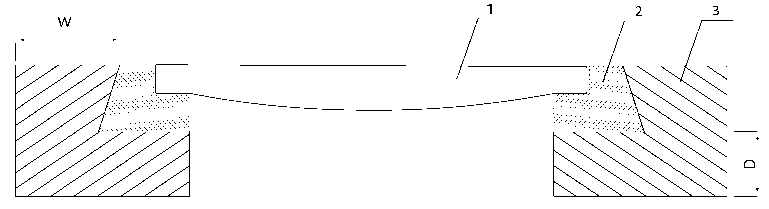

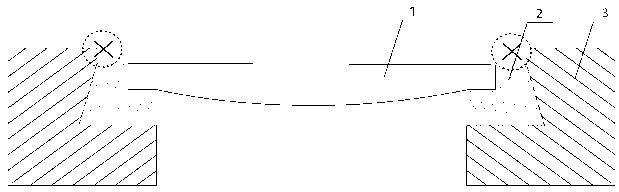

The clear opening (co in short) of the frame should be equal to the manhole co, or larger than the manhole diameter, which can avoid the part of the frame hang in the air, the wrong transfer of loading pressure.

How to choose the dimension of manhole cover?

The clear opening (co in short) of the frame should be equal to the manhole co, or larger than the manhole diameter, which can avoid the part of the frame hang in the air, the wrong transfer of loading pressure.

- Manhole Cover

- Frame

Measures of Remediation

Notice : The basic level of the manhole should be compacted and level to avoid subsides of the manhole cover after massive pressure. The masonry wall should be integrity, the close up should be uniform.

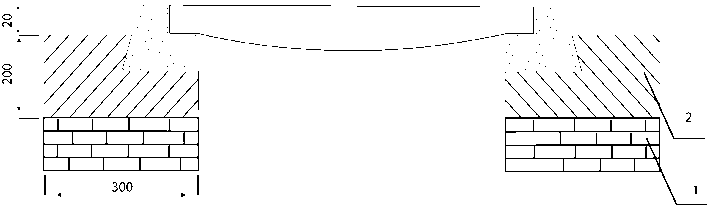

The frame should be fastness well

The frame bottom should be casting the concrete C25 or even better, the frame around concrete width (w) should be more than 300 mm. the bottom (D) concrete should be more than 200 mm.

- Manhole Cover or Grate

- Frame

- Around Concrete

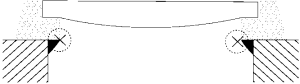

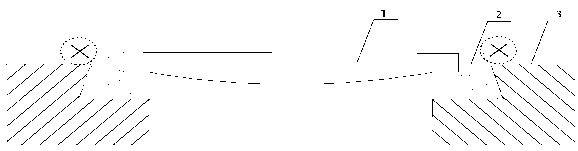

The manhole cover surface should be highly consistent with the ground:

Estimation error range <+- 2mm

- Manhole Cover or Rain Grate

- Frame

- Ground

Asphalt pavement construction program

Fasten the frame by pre-cast concrete (c25, c30, c35), and maintain the pre-cast concrete more than 72 hours, then pave the asphalt. The cover frame should avoid the large-scale construction achinery rolling on.

- To support and fasten, there must be 10-20mm cement paste under the frame.

- The frame should be surrounded by concrete with 300 mm width, and 200mm height.

- The Frame can be 20mm above the ground for asphat pavment.

- Manhole co should be equal or less than the frame co.

- Concret base.

Asphat material

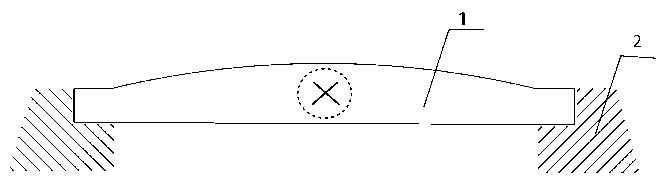

Manhole cover right side up

Reverse side up will easily broken and reduce the loading capacity.

- Manhole Cover or Rain Grate

- Frame

Expansion Backup Gap

If the cover or grate have no frame, we should guarantee the expansion backup gap. (total gap width normally be 3-5 mm.)

Precautions Before/After Installation

- Ensure that the frame is completely resting in concrete on all 4 sides.

- If it is continuous channel, ensure that the frame is completely resting in concrete on 2 sides.

- Ensure that right capacity cover is installed as per EN 124 classification. Always install cover of proper load capacity recommended by company’s technical person.

- Don’t throw/drop the cover or frame on ground; else it will cause heavy damage to FRP covers.

- choose a suitable manhole cover as per the required Load Bearing Capacity as mentioned in the technical datasheet.

- Do not try to insert pry bars, and don’t use hammer. It can damage the covers.

- Use all the lifting slot while lifting the DUDHI FRP covers.

- Dudhi FRP Manhole covers can be lifted using lifting keys provided which engage in key-slot in cover. FRP Gully Covers/Gratings can be lifted using bare hand.

- Although first, they may need to loosen the cover if it jammed in the frame, usually the result of compacted dirt, corrosion and traffic impact.

- Always keep the plastic wrap intact on cover till the time of finalisation of the site work to reduce hazardous operational damages.

- Don’t stand/park a vehicle on stacked covers; else it can cause heavy damage on cover. It will also void the warranty.

- Please avoid direct contact with chemicals, acids, fire with the FRP Covers.

Maintenance/Cleaning

Dudhi FRP covers are durable, and repel stains, bacteria, mould and mildew growth. But, like SFRC/RCC and CI/DI covers, FRP covers are not immune to dust and dirt build-up. You don’t need a specialized cleaner to remove debris from the covers. Cleaners you already have in your home or business, along with several other basic household supplies, are all you need to keep your FRP covers stain-free.

Step 1: Mix in a bucket 1/2 cup (150 ml) of liquid soap and 2 litre of warm water. Wear latex gloves to keep your hands clean. Stir the mixture with a sponge or soft scrub brush. Fill another bucket with 1/2 gallon of warm water and set the bucket off to the side.

Step 2: Move any vehicles, rugs or accessories next to or on the FRP covers to another area.

Step 3: Wring out excess mixture and scrub one FRP covers with the mixture-soaked sponge or scrub brush. Re-dip the sponge or scrub brush in the mixture, wring out the excess and continue scrubbing the covers until it is clean. For stubborn stains, spray the stain with a general-purpose household cleaner / NC Thinner and let it stand for five to 10 minutes. Scrub the stain vigorously with the damp sponge or soft brush.

Step 4: Dip a large, soft cloth or rag in the bucket of warm water you set off to the side in Step 1. Wring out the excess and wipe the FRP covers you just cleaned to remove any mixture residue and remaining debris.

Step 5: Re-dip the sponge or scrub brush in the bucket containing soap mixture and repeat Steps 3 and 4 for the next FRP covers that needs cleaning.

Step 6: Let the covers dry naturally or if required dry the covers with a clean, large cloth or rag.

Product Name: FRP Manhole Cover, Grating and Recessed Cover

Composition:The FRP manhole cover is made from a mixture of fiberglass, resin, and other additives. The individual components of the FRP manhole cover are listed below:

Fiberglass:

CAS No.: 65997-17-3

Chemical formula: N/A

Percentage: >70%

Resin:

CAS No.: 9003-36-5

Chemical formula: (C2H3Cl)n

Percentage: <30%

Other Additives:

CAS No.: Mixtures of several chemicals

Chemical formula: N/A

Percentage: <5%

Physical and Chemical Properties:

Appearance: Rectangular, round or square manhole cover

Weight: 10-100 kg

Density: 1.5-2 g/cm³

Melting Point: Not applicable

Flash Point: Not applicable

Boiling Point: Not applicable

pH: Not applicable

Water Solubility: Not soluble in water

Vapor Pressure: Not applicable

Vapor Density: Not applicable

Odor: None

Hazards Identification:

The FRP manhole cover is considered to be a relatively safe product. However, when it is heated to high temperatures, it can release hazardous fumes which can be harmful to health. In addition, when the FRP manhole cover is cut, it can produce fine fibers which can cause irritation to the skin, eyes, and respiratory system. Therefore, users are advised to wear protective equipment such as gloves, goggles, and masks when handling the product.

Fire and Explosion Hazards:

The FRP manhole cover is not considered to be a combustible material. However, if it is exposed to high temperatures, it can release hazardous fumes which can cause a fire. If the product is cut or drilled, it can produce fine fibers which can ignite when exposed to a heat source.

Health Hazards:

Inhalation: When inhaled in large quantities, the fine fibers produced when the FRP manhole cover is cut can irritate the lungs and cause respiratory issues. If inhaled chronically, they may lead to other respiratory issues such as lung cancer.

Skin Contact: Fine fibers produced when the FRP manhole cover is cut or drilled can cause skin irritation.

Eye Contact: Fine fibers produced when the FRP manhole cover is cut or drilled can cause irritation and damage to eyes.

Ingestion: The FRP manhole cover is not considered to be toxic if ingested.

Environmental Hazards:

The FRP manhole cover does not cause any immediate concern to the environment.

First Aid Measures:

Inhalation: If large amounts are inhaled, move to fresh air and seek medical attention immediately.

Skin Contact: Do not rub the affected area. Rinse gently with plenty of water.

Eye Contact: Immediately flush the eyes with plenty of water for at least 15 minutes. Seek medical attention if irritation persists.

Ingestion: Rinse the mouth thoroughly with water. Drink plenty of water and seek medical attention if necessary.

Firefighting Measures:

The FRP manhole cover does not cause any immediate concern for firefighters. However, if the product is exposed to high temperatures, it can release hazardous fumes which can cause a fire. Firefighters should wear proper protective equipment such as masks and gloves when dealing with this product.

Handling and Storage:

The FRP manhole cover should be stored in a dry and cool area. This product should be handled according to proper safety procedures, which include wearing protective clothing such as gloves, goggles, and masks when handling the product.

Exposure Controls/Personal Protection:

Exposure limits for the individual components of the FRP manhole cover are not available. Therefore, employees should wear personal protective equipment such as gloves, goggles, and masks when handling the product.

Conclusion:

The FRP manhole cover is considered to be a safe product if handled properly. However, it is not without its potential hazards such as the release of hazardous fumes when exposed to high temperatures and the production of fine fibers when cut or drilled. Adequate protective measures should be taken when handling this product. This data sheet should be read by everyone who comes into contact with this product to ensure safe handling and working conditions.

- Dudhi warrants to the original purchaser that our products are free from manufacturing defects and any faulty product found within 2 years from date of invoice shall be replaced or repaired.

- The warranty starts from the date of invoice.

- Any product believed to be faulty should be reported to Dudhi within 7 days from the date of dispatch.

- Following assessment by Dudhi team, any fault found and if covered by this warranty will be rectified by either replacement or repair of the product. If deemed necessary, the product may be returned to factory for repair & buyer will bear both side transportation cost.

- The FRP product must not have been misused, handled carelessly, nor been damaged, neglected or used in abnormal conditions.

- The product must not have been modified, altered in any way, or repaired by anyone other than a staff of Dudhi or their appointed representative.

- This warranty does not apply to normal wear and tear caused by regular use.

- Damage such as dents, scratches, marks and tears to surface or FRP covers that have happened during normal use are not covered by this warranty.

- Small hairline cracks which may appear on the edges and surface of FRP covers due to mishandling, and any change in appearance or colour due to usual weathering / exposure to extreme site condition due to use of concrete, cement, lime stone etc are considered entirely natural to Dudhi FRP covers and are not covered by this warranty.

- Faulty installation, installation of low load bearing cover in area requiring high load bearing & sinking ground are not covered under this warranty.

- In case of Double‐seal type covers with EPDM rubber ring, we provide 1 year of warranty on the rubber ring.

- The warranty will only be valid if proper installation, maintenance and cleaning have been carried out in accordance with Dudhi Instruction Manual.